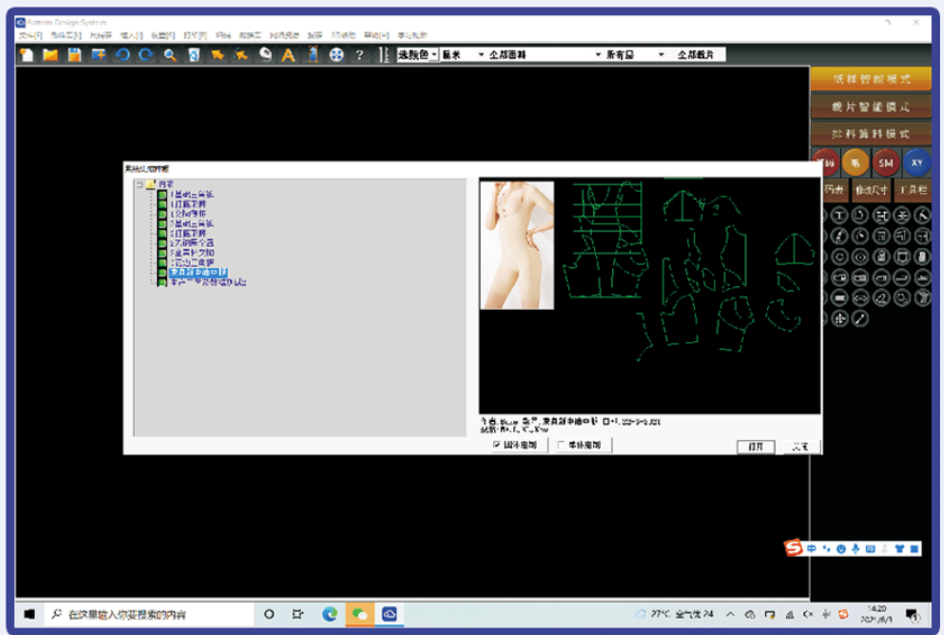

Product Introduction

The Bok Intelligent Underwear CAD System is developed specifically for underwear enterprises. The system is more professional and has a higher degree of accuracy. By adopting parametric design technology, the system can achieve powerful linked modifications and automatic grading, significantly improving the efficiency and accuracy of pattern modification and grading. It is especially suitable for small-batch and quick-response orders as well as personalized customization. The system integrates a powerful super nesting function. Within one system, it can realize integrated operations such as pattern making, grading, nesting, and material calculation, featuring excellent convenience and cost-effectiveness. It can effectively help underwear enterprises improve product quality and production efficiency, reduce material costs and labor costs, and enhance the competitiveness of enterprises.

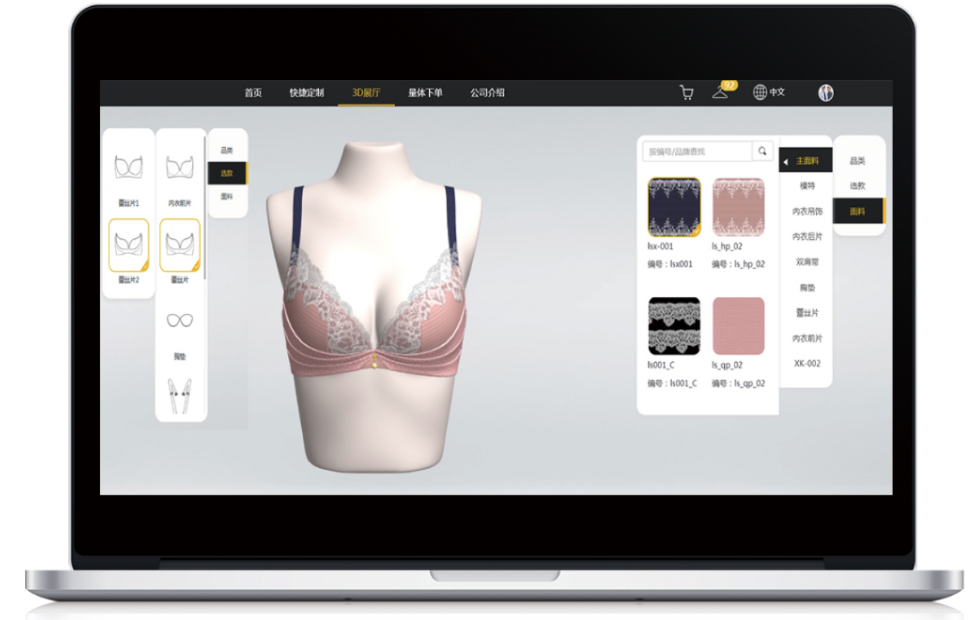

Bok Underwear Garment Order Receiving System

It is developed for the transformation towards underwear customization, helping underwear enterprises achieve order digitization, design networking, and production intelligence. Compared with traditional Internet shopping malls, the Bok Underwear Garment Order Receiving System can bring about a disruptive business model. Garment merchants don’t need to produce first and then sell. Instead, they can sell first and then produce. It supports both bulk orders and personalized individual orders. It also supports placing orders with standard sizes, as well as placing orders based on body measurements and orders for size modification. Users can participate in product design through the 3D virtual network system, and can see in real time the finished garment effects generated by choosing different styles, components, and fabrics. They can even independently set personalized designs such as embroidered characters and patterns. The powerful enterprise backstage supports functions such as order management, financial management, product management, and customer management. It can also be integrated and connected with the enterprise’s ERP system, financial system, inventory system, production system, and logistics system, etc. It is a powerful weapon for underwear garment enterprises to achieve the C2B transformation.

Core Advantages of the Underwear System:

A more professional underwear system

It is designed and developed specifically for underwear enterprises, with a large number of detailed treatments carried out for underwear pattern making. The system comes with a built-in underwear pattern material library. Users can gradually establish their own pattern material libraries, and achieve rapid pattern changes and style modifications through these pattern material libraries. It can accelerate the efficiency of design and research and development, and enhance the brand’s competitiveness.