For personalized customization

Individual customization has the following multiple requirements for pattern making:

For individual customization, all dimensions of the individual must be accurately measured to ensure a perfect match between the paper pattern and the individual’s figure. For example, in clothing customization, dimensions such as shoulder width, bust, waist, hip, sleeve length, and pant length need to be accurately measured.

The pattern should be designed according to the customer’s personalized needs to create unique styles. Meanwhile, combined with the customer’s body characteristics, the pattern should be designed to showcase the advantages of the figure and conceal the deficiencies.

When making the pattern, the physical properties of the selected material, such as stretchability, softness, thickness, etc., as well as the texture and pattern direction of the material, should be fully considered to adapt the pattern to the material characteristics.

The design of the paper pattern should consider the actual production process and conditions to ensure that the cutting, splicing, sewing, and other processes can be efficiently and high – quality completed in actual production.

Through reasonable paper pattern design, optimize the layout, improve the utilization rate of the fabric, reduce fabric waste, and at the same time, select the appropriate plate – making process and accessories to control the production cost.

Usually, a fitting is required. According to the fitting results, the paper pattern is carefully adjusted to meet the customer’s personalized needs.

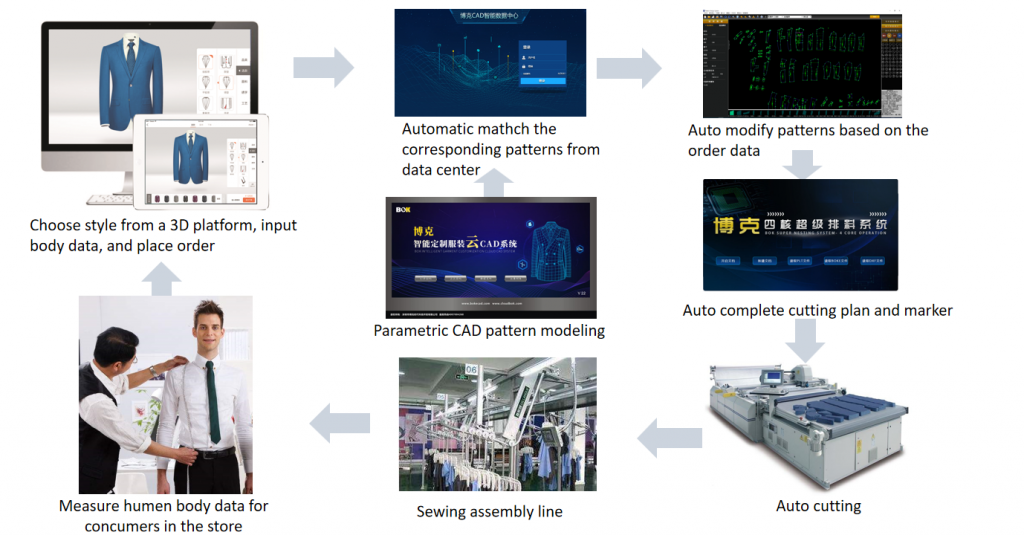

What can Bok do?